Metal Pressings

Working with a wide variety of materials which we are always very happy to discuss, “what material will produce the right result” for your needs.

Typical materials which we work with are: –

- Spring Steel

- High Carbon Steel

- Low Carbon Steel

- Nickel Plated Carbon Steel

- Stainless Alloys

- Non-Ferrous Metals

- Elgiloy®

- Hastelloy®

- Monel®

- Inconel®

- Titanium

- and More

J T Pearce (Springs) Limited manufacture a wide a variety of pressings to customers’ exact design requirements. We offer a full design and prototyping service. Precision flat and 3D forms and components in low to medium volume are a specialty.

Metal Pressings Finishing

Pressings can be finished in the following ways: –

- Rotary vibration finishing

- Projection welding

- Spot welding

- Riveting and assembly work

Metal Pressings Coating

Where required we can

- Zinc Plate

- Galvanise

- Hot dip galvanise

- Powder coat

I have found J T Pearce to be most helpful in both the design and manufacture of our products. We are not experts but with help of Es and his staff we have been able to overcome some issues previously experienced. I would highly recommend J T Pearce.

Technical Manager.

(Manufacturing Company)

Metal Pressings

From simple shapes such as this metal pressing to create a cable clip

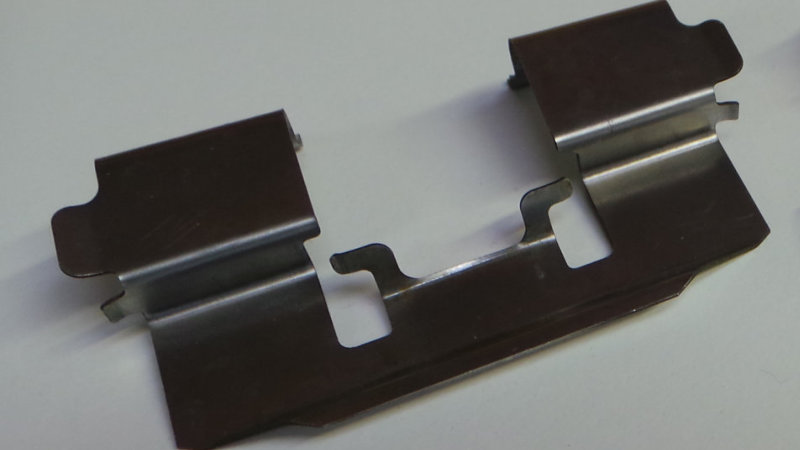

To much more intricate shapes such as this part for a brake assembly, and all shades in between.

To much more intricate shapes such as this part for a brake assembly, and all shades in between.

Washers

The humble washer is a vital component of any fastener system and here at JT Springs we have the capacity to produce washers in volume, in a wide variety of materials.

To much more intricate shapes such as this part for a brake assembly, and all shades in between.

Wave Washers

Part way between a spring and a washer, you can specify pretty well any design imaginable, in a wide variety of materials.

Prototypes

These can vary from the simple to the highly complex.

Working from a: –

- Sample

- Cut away

- Drawing, CAD data, sketch, or discussion.

Our collaborative approach allows us to keep lead times to a minimum, where traditional lead times can be 12-weeks it is not uncommon for us to cut that in half.

If you are trying to get a product to market long lead times can be expensive in terms of missed marketing opportunities.

With our in-house skills and physical equipment we have the capability to accelerate your product development.

Materials we frequently work with include: –

- CS70

- CS80 Hardened and Tempered

- Stainless Steel 302/304/316

- Brass / Beryllium Copper

- Phosphor Bronze

New projects welcome.